Future of Performance

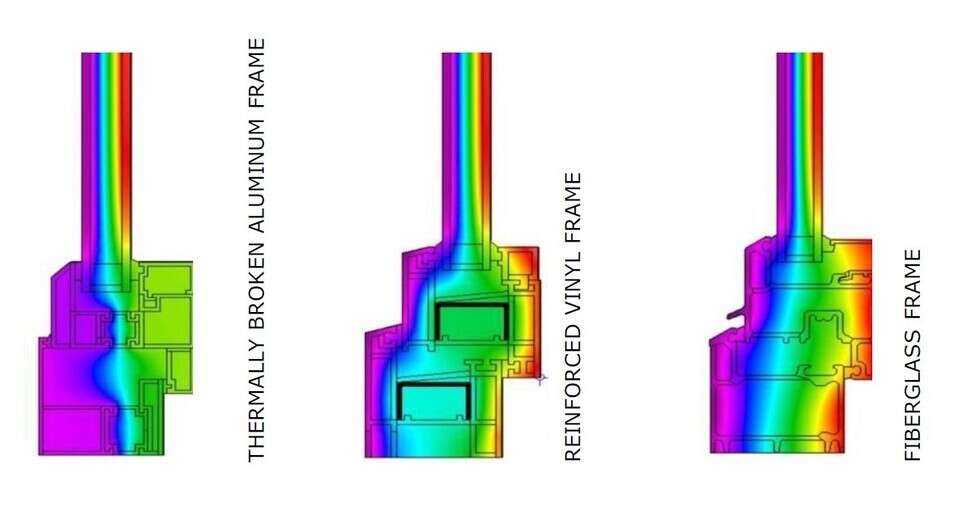

Why Fiberglass?

Fiberglass is an ideal structural material for window and door frames, which is why Cascadia has used a proprietary, high glass-fiber-to-resin formula for more than a decade. Beyond its high strength and thermal efficiency, Cascadia's pultruded, thermoset fiberglass frames contain roughly 58% recycled content, low VOC's and represents less embodied carbon compared to vinyl or aluminum.

Not susceptible to decay or corrosion, fiberglass also expands and contracts with temperature change at roughly the same rate as the adjacent IGU. This extends the longevity of window seals and gaskets, reducing maintenance costs. Combined with a modeled lifespan of 50-80 years, fiberglass represents the future of high-performance windows and doors.